Every bespoke timber staircase we create is a work of art - which is why we only take on a handful every year.

Our staircases are anything but standard - so if you are looking for a straight flight, we are probably not the company for you.

But if you are looking to create a stunning feature staircase with curves, fantails or spirals, we can certainly help - and here is how we do it

From the very first contact, you will see how we do things differently.

We will analyse your drawings carefully and discuss your plans, your materials, your design to ensure we fully understand your project.

We may offer a few suggestions and ideas using our extensive experience and expertise before preparing a proposal and costing for you to consider.

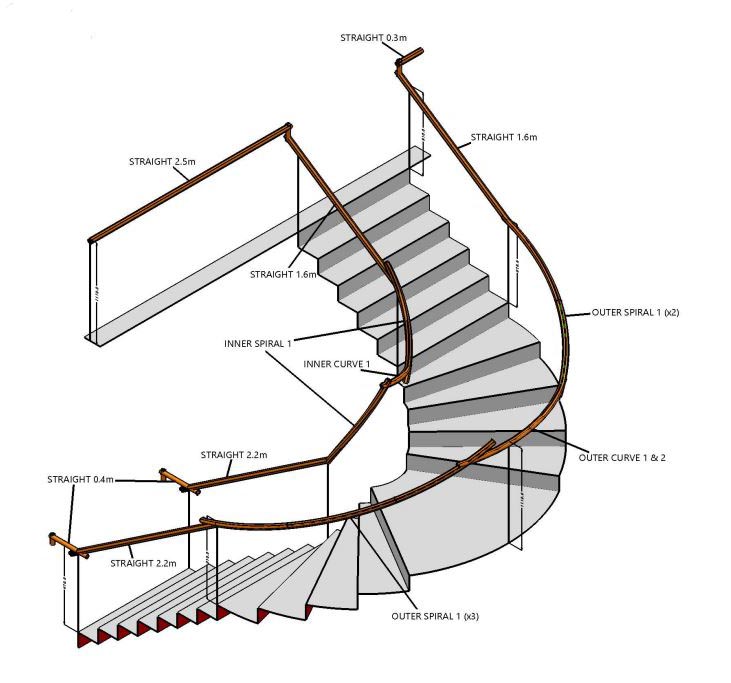

Once your order is placed our design team will take your drawings and produce 3D visuals to start bringing your staircase to life.

These renders form the basis of our manufacturing programme and allow us to assess the feasibility of every aspect of the staircase, addressing any technical challenges we identify.

Once checked and approved, our programming team take the drawings and break them down into the various components for setting out and machining.

Once your order is placed our design team will take your drawings and produce 3D visuals to start bringing your staircase to life.

These renders form the basis of our manufacturing programme and allow us to assess the feasibility of every aspect of the staircase, addressing any technical challenges we identify.

Once checked and approved, our programming team take the drawings and break them down into the various components for setting out and machining.

Before any staircase is despatched, our staircase team will construct the core structure within our test area.

Every component will be assessed and stress-tested to ensure it is absolutely perfect. with a flawless finish, ready for the finishing touches to be added.

The staircase is then carefully de-constructed and packaged ready for transportation to your site.

Our fantastic in-house installation team receives praise and admiration wherever they go - not just for the quality of the job they deliver but also for their amazing work ethic and willingness to go that extra mile to help.

Whilst every component is individually checked before despatch, we know that certain on-site conditions can change at the installation stage.

Our highly skilled craftsmen have extensive experience handling these issues, and you can be assured of a superior quality finish to your staircase.

We can also offer a full french-polishing solution to achieve that perfect finish.